We can use M commands to modify and toggle the functions of these components. They control all the other miscellaneous functions of the printer such as the sensors, heaters, fans, and even the printer’s sounds. M commands differ from G commands in the sense that they start with an M. You can visualize and test out your G-Code commands here. We’ll look at other various G commands later. The G1 command means the printer should move in a straight line at the specified feed speed.

#How to convert a file to gcode code

So, if we put it all together, the line of code tells the printer to move to coordinate at a speed of 90mm/s while extruding 12.900mm of material. The comment is not part of the executable code.

F – F is the speed or feed rate of the printer.G – The G signifies the line of code is a G command while the number after it represents the printer’s mode.11 – This indicates the line of code that is running.

Let’s go through the line and explain the commands: It is also used in controlling the motion and orientation of the printer’s different parts.ġ1 G1 F90 X197.900 Y30.000 Z76.000 E12.90000 Comment G commands control the different modes of the printer. Let’s take a look at both of them: G Commands In the G-Code programming language, we have two types of commands the G command and the M command. Let’s go through some common notations in G-Code and what they mean. In situations like this, knowledge of G-Code can come in handy to help accomplish the task. But sometimes, situations can arise where a user might need to tweak or modify some print settings that can only be found in the printer’s G-Code profile. How Do You Translate & Understand G-Code?Īs we said earlier, most of the time, regular users might not even need to edit or modify the G-Code.

#How to convert a file to gcode software

These 3D models are put through a slicer software to convert into G-Code files which 3D printers can understand. The main file that 3D models are made from are STL files or stereolithgraphy files. Yes, all 3D printers use G-Code, it is a fundamental part of 3D printing. The slicer transforms the STL file into lines of code that tell the printer what to do at every point throughout the printing process. It is created from the 3D model’s STL file using a program known as a “Slicer”.

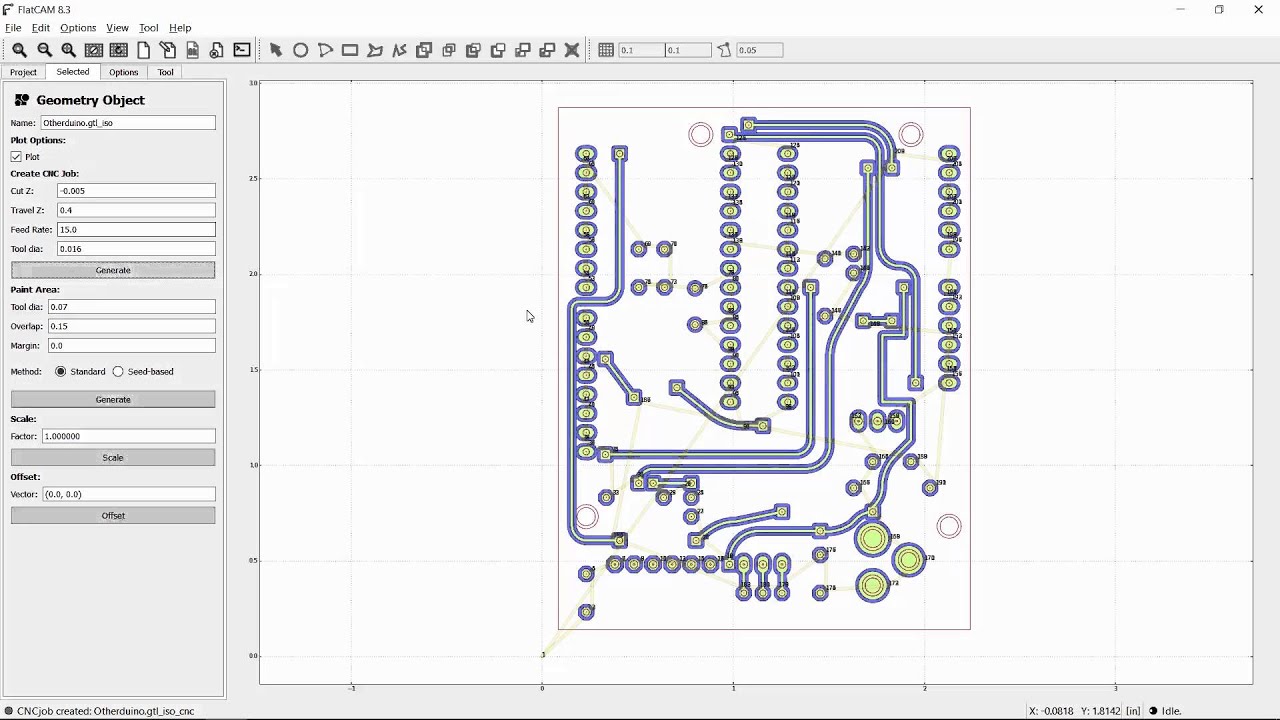

It controls the extrusion speed, fan speed, heated bed temperature, print head movement, etc. G-Code is a programming language containing a set of commands for controlling virtually all of the printer’s print functions. Build Plate adhesionĪ skirt and brim are just taking the outline of the build-plate intersection and surround that with outlines.Ī Raft is generated like the simple support case, but taking the whole base of the object, adding a little edge around it and then generating the support grid there.6.3 gCode Viewer What is G-Code in 3D Printing? Tree support on the other tries to generate a support structure that bends around the object without intersecting and only relying on the support of itself. The most simple form of support generation simply generates a grid pattern between such areas and the bed or next surface below. Under standard settings, this would be about less than 60° to the XY-plane with the normal of the surface having a negative Z-component - which means that a needle poking out of that surface points towards the bed. Support calculationĪ slicer usually identifies areas that need support by calculating at which angle an STL Surface cuts a given plane cut. The more paths there are and the smaller the triangles that are cut up, the more complex the solution process becomes and the longer it takes. Then it uses this outline to generate the infill pattern, for example, as explained here. A Watertight STL - for slicing purposes - has surfaces that always create closed outlines if cut parallel to the XY plane.Ī Slicer does exactly that: it creates plane-cuts at the indicated Z-heights, takes the plane-cut's outline(s), and decides a direction and order in which to follow the generated path.

0 kommentar(er)

0 kommentar(er)